vertical submersible slurry pump manufacturers

Latest articles

Pumping slurry can cause excessive wear and tear on the pump and its components as the mud can clog the suction and discharge lines.

vertical submersible slurry pump manufacturers...

vertical submersible slurry pump manufacturers 【vertical submersible slurry pump manufacturers】

Read Morefactors-to-consider-when-choosing-a-slurry-pump

vertical submersible slurry pump manufacturers...

vertical submersible slurry pump manufacturers 【vertical submersible slurry pump manufacturers】

Read MoreFrom an operational point of view the stuffing box is different as it requires some leakage to ensure lubrication and to prevent heat build up. The mechanical seal box should be leak free.

vertical submersible slurry pump manufacturers...

vertical submersible slurry pump manufacturers 【vertical submersible slurry pump manufacturers】

Read MoreRubber is lighter and softer than other wear lining materials. This aids installation because it is easier to lift and install quickly and efficiently. Positive results for the health and safety of workers in the field.

vertical submersible slurry pump manufacturers...

vertical submersible slurry pump manufacturers 【vertical submersible slurry pump manufacturers】

Read MoreSome models can generate discharge pressures up to 260 ft. (80 m).

vertical submersible slurry pump manufacturers...

vertical submersible slurry pump manufacturers 【vertical submersible slurry pump manufacturers】

Read MoreChromium White Iron, Super High Chromium Hypereutectic White Iron, Low Carbon High Chromium Alloy, Carbon Steel,

vertical submersible slurry pump manufacturers...

vertical submersible slurry pump manufacturers 【vertical submersible slurry pump manufacturers】

Read MoreThe selection of a dredge or >slurry pump can be a challenging process that can be simplified by understanding the main factors behind the smooth operation of a pump. In addition to providing more efficient performance, the right dredge pump requires less maintenance, lower power and a relatively longer life.

vertical submersible slurry pump manufacturers...

vertical submersible slurry pump manufacturers 【vertical submersible slurry pump manufacturers】

Read MoreThe solution is to choose a >heavy duty slurry pump and, just as importantly, to use a custom built unit with replaceable parts. At Aier Machinery, building your custom slurry pump is one of our areas of expertise. We design your slurry pump to your specifications and application.

vertical submersible slurry pump manufacturers...

vertical submersible slurry pump manufacturers 【vertical submersible slurry pump manufacturers】

Read MoreWhat is a dredging pump?

vertical submersible slurry pump manufacturers...

vertical submersible slurry pump manufacturers 【vertical submersible slurry pump manufacturers】

Read MoreSelecting And Operating A Slurry Pump

vertical submersible slurry pump manufacturers...

vertical submersible slurry pump manufacturers 【vertical submersible slurry pump manufacturers】

Read More

Popular articles

- Especially when the dredging depth reaches 20m or more, the above situation will be more obvious. The use of underwater pumps can effectively improve the above situation. The lower the installation position of underwater pumps, the smaller the suction resistance and vacuum, which can obviously reduce the losses during the work and improve the working efficiency. The installation of underwater pump can effectively increase the dredging depth and improve the ability to transport sediment.

- To reduce component wear, most centrifugal slurry pumps run at fairly low speeds - typically less than 1200 rpm. Find the optimum position that allows the pump to run as slowly as possible but fast enough to prevent solids from settling out of the slurry deposit and clogging the lines.

- Using rubber as a wear lining material means

- -When pumping abrasive slurries, it is essential to use wear-resistant components with a high chromium content. But more is not always better - above 25%, the impeller becomes brittle.

- Dredge Pump

- The winch dredger is usually equipped with a hull-mounted dredge pump, which has an impeller centered at or below the draft line for further production and improved suction efficiency.

Latest articles

-

The dredge pump is designed to draw sediment, debris and other hazardous materials from the surface layer into the suction pipe and transport the material through the pipe to the discharge site. The pump must be able to handle common solid debris of various sizes that can pass through the pump, thus minimizing the downtime required for cleaning.

-

What is the best seal arrangement for the application?

-

>Slurry Pump

-

testing station in the world, and its test capacity can reach 13000m³/h. Annual output of our products is 10000

-

All manufacturers are consistently involved in product development in the long and short term. Customers should expect to benefit from these developments in a number of ways: increased efficiency, increased reliability, reduced operating costs, or a combination of both.

-

If a centrifugal pump, is the design and material used to construct the impeller suitable for pumping slurries?

Links

- The cost factor is another critical consideration for buyers

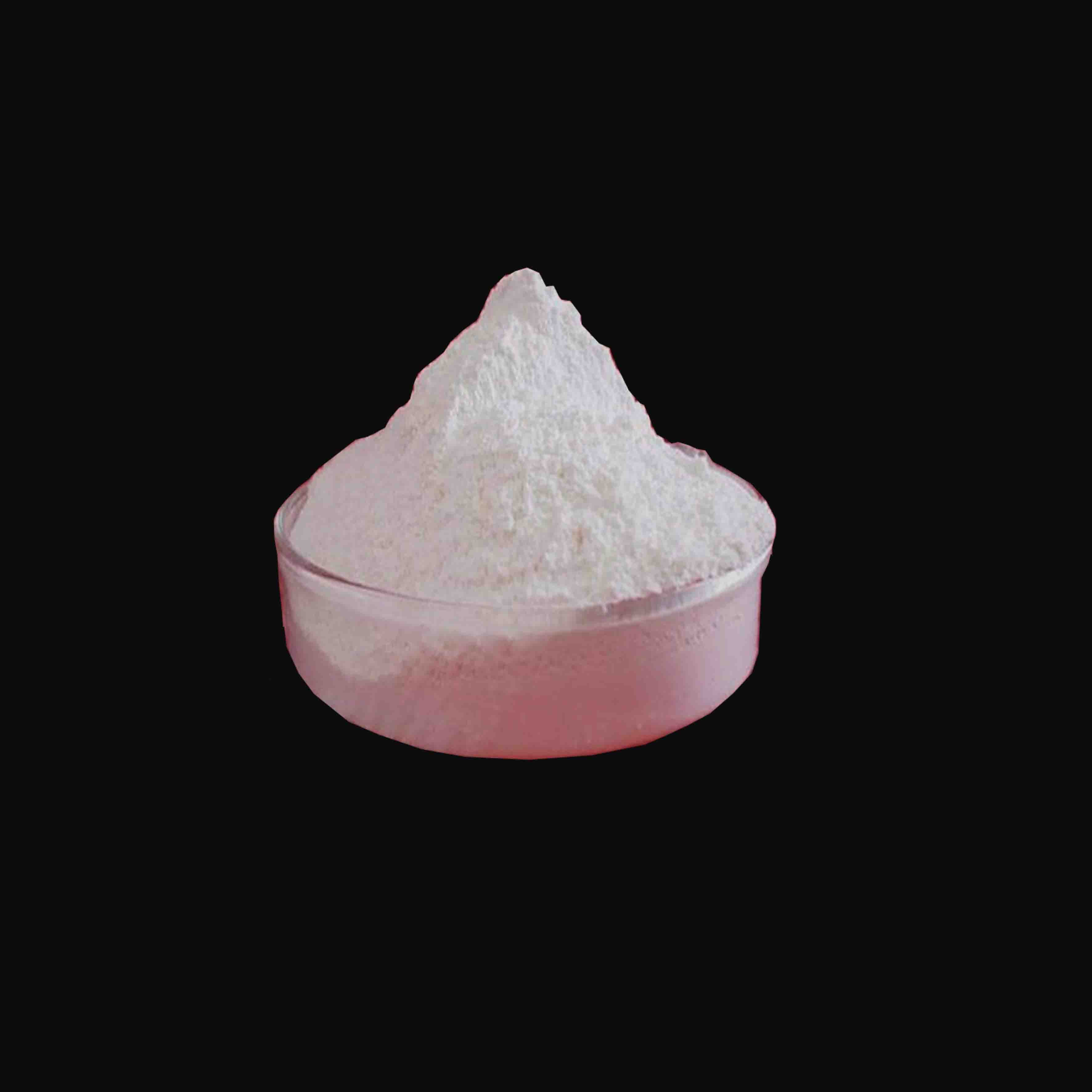

- * Specializes in the production of high-purity lithopone B311, suitable for use in high-end applications.

This might involve using dust suppression systems, storing TiO2 in airtight containers, and implementing a clean and well-ventilated storage area This might involve using dust suppression systems, storing TiO2 in airtight containers, and implementing a clean and well-ventilated storage area

This might involve using dust suppression systems, storing TiO2 in airtight containers, and implementing a clean and well-ventilated storage area This might involve using dust suppression systems, storing TiO2 in airtight containers, and implementing a clean and well-ventilated storage area wholesale tio2 safety. Regular inspections and maintenance of these facilities are necessary to maintain safety standards.

wholesale tio2 safety. Regular inspections and maintenance of these facilities are necessary to maintain safety standards. We understand that our customers require materials that are reliable and effective, and we strive to exceed their expectations with every shipment We understand that our customers require materials that are reliable and effective, and we strive to exceed their expectations with every shipment

We understand that our customers require materials that are reliable and effective, and we strive to exceed their expectations with every shipment We understand that our customers require materials that are reliable and effective, and we strive to exceed their expectations with every shipment titanium dioxide anatase supplier.

titanium dioxide anatase supplier.The European Food Safety Authority (EFSA) has concluded that titanium oxide should not be considered safe as a food additive, due to uncertainties about possible inflammation and neurotoxicity (9Trusted Source).

TiO2 comes in many different forms. However, only a few of these forms are considered food-grade (acceptable to be added to food). Many studies that raised concern about the safety of TiO2, including the concern for genotoxicity, used forms of TiO2 that are not considered acceptable for use in food and have different properties than food-grade TiO2. Other studies did use food-grade TiO2, but took steps to break the material down into smaller particles than what would normally be found in food.

In order to achieve the same solids content, the larger filler and the binder should be reduced if necessary.

Public health groups urge FDA to cancel titanium dioxide in food, by Center for Science in the Public Interest, May 30, 2023

Dawn Polymer Material, a brother company of Dawn Titanium, has successfully applied for an Initial Public Offerings (IPO), which has started rumours about Dawn Titanium is also about to apply for the IPO.